MOULDING

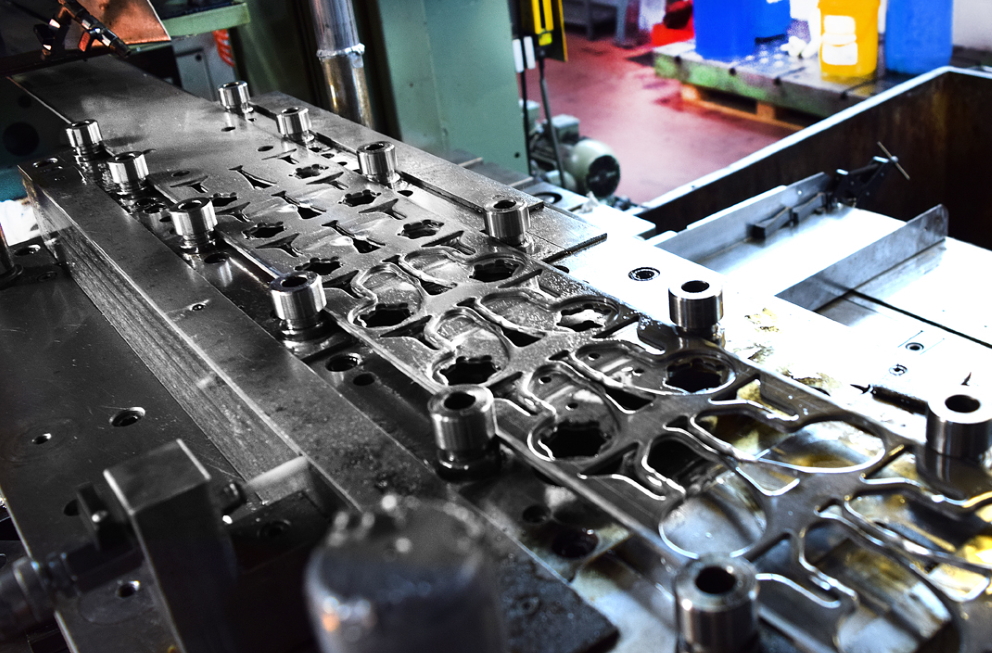

I.s.a Vascelli is able to produce a wide range of moulded sheet products, made through shearing, drawing, embossing, bending and welding operations.DRAWING

The sheet metal drawing department uses hydraulic presses with variable power up to 300 tons. We perform operations of deep moulding, coining, calibration, on materials such as stainless steel, aluminium, cold-rolled, sound-absorbing sheet.

Some product examples are: Filters, Oil Cups, Flanges, Covers, Brackets, Panels, and numerous other products.

The department is also equipped with a transfer press for automatic production.

SHEARING

The sheet metal shearing department is equipped with mechanical presses with variable power from 25 to 400 TONs served by electronic ballasts. We produce a considerable quantity of moulded products, such as: covers, brackets, eyebolts, guards, platforms, bulkheads, etc.

The most commonly used materials are strips, bars and sheets of stainless steel, aluminium and its alloys, high strength sheets, hot and cold rolled. The thicknesses worked range from 0.4 to 10mm.

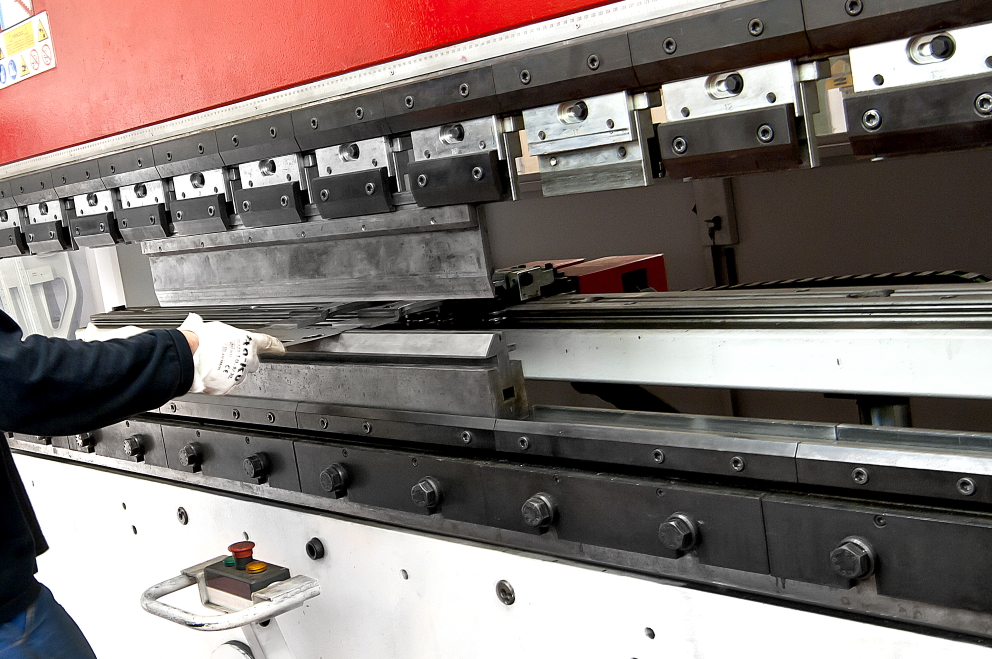

FOLDING

The bending department is equipped with two CNC bending presses capable of performing a large number of different types of bending on sheets up to 5mm thick.

This processing cycle allows bending operations to be carried out without having to resort to the construction of specific moulds, thus reducing the customer’s production costs for small series.

ADDRESS

Via delle Basse, 12

43044 Collecchio (PR) Italy

P.I. 01534260342

cap.soc. 100.000,00 € int. vers.

Numero REA 161353

CODICE SDI: M5UXCR1

PHONE

+39 0521 805725

FAX : +39 0521 800067